The impact of rising food prices is being felt, with consumer price inflation increasing by more than 9% in less than a year in Canada and the United States. Restaurateurs are greatly affected, having to reduce portion sizes.

And what about food waste… it is a major issue that the food industry faces everyday. About 24% of all food goes to waste in the US. That’s about 54 million tons of food.

Let’s List 6 Challenges in the Restaurant Industry

- Increasing food costs

- Food waste

- Labor costs

- Inventory management

- Customers demand more quality

- Supply chain pressures

Did you know that vacuum packaging can solve 4 of these challenges out of 6?

And get even more

- Extend the shelf life of food by 2 to 5 times

- Ensure food safety by blocking contaminants

- Eliminate food waste by pre-portioning food

- Save space in the fridge by reducing the size of all packages

- Save time by optimizing inventory management

- Reduce food costs – No more waste!

Let’s Hear from a Restaurant Owner

Bob Vasaturo – Owner of Westshore Pizza in Florida

It’s been over a year since Bob decided to add a vacuum sealer to his kitchen to improve the freshness of his food and avoid throwing food away.

When focusing on providing the highest quality to your customers, the vacuum sealer will be your go-to.

‘’Before, we used to pack in standard packages, there was always air left inside. The meat didn’t stay as fresh and we had to throw it away and rotate it frequently”, says Bob.

Bob’s Savings with His Commercial Vacuum Sealer

5% to 8% savings in food cost each year

-

- It sounds high, but with the elimination of food waste and the price of food, it makes a big difference at the end of the year.

US$12,000 saved each year

-

- ‘’Its difficult to put an exact number on it, but I can say that I certainly save close to $12,000 in food a year with my sealing machine. That’s a big deal!”, says Bob.

It Pays Itself Within 5-9 Months

-

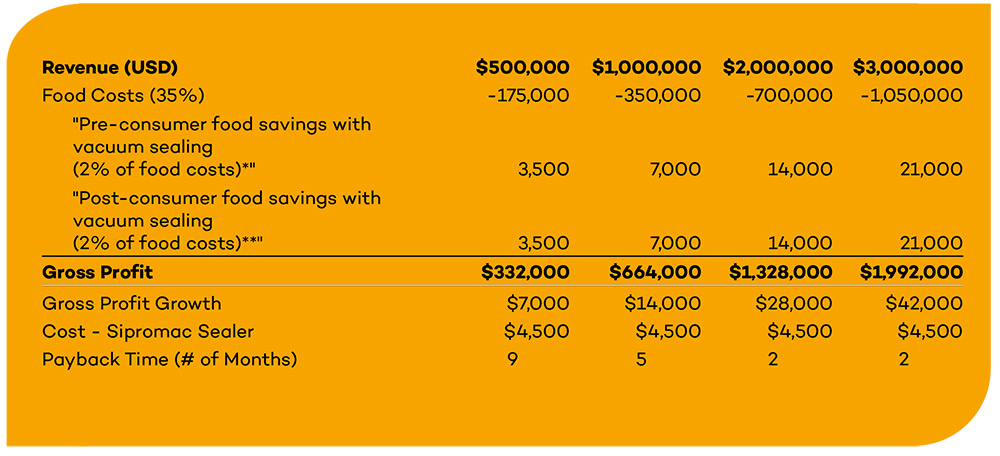

- A Sipromac commercial vacuum sealer costs around US$4,500 (see table below) and it will lasts you more than 25 years. With the above-mentioned savings in food costs, the machine can pay for itself in less than 8 months.

Labor savings

-

- ‘’We used to cut a quarter stick of salami and turkey at a time. Now we can cut it all at once, it saves us a lot of time. I can cutat least one employee on food prep.’’

Food quality

- ‘’ The vacuum sealer has eliminated our freezer burn problem and our product lasts 3 to 4 times longer. It’s so fresh when you open it, it’s like you just sliced it.’’

Types of Savings with a Vacuum Equipment

Pre-consumer food savings:

This category includes food before it reaches the client’s plate. Savings can be achieved by re-packing bulk foods, sealing items with a shorter shelf life like meat and fish, and optimizing food preparation. Vacuum sealing helps you save food by extending shelf life by 2-5 times.

Post-consumer food savings:

This category includes food after it reaches the client’s plate. Vacuum sealing helps you save money by allowing you to standardize and control portions, therefore saving food before it reaches the customer, which would go uneaten. That’s profits directly in your pockets.

Here’s a breakdown of those savings depending on your turnover.

A Vacuum Packaging Machine Can Be Your Solution

By pre-portioning food and vacuum sealing it, you avoid waste and you get better inventory management.

Investing in equipment that will help you reduce your costs by eliminating food waste in your kitchen is your best option. Do like Bob and stop throwing money out of the window. You’ll see that it’s a game-changer!